Modern furnaces benefit from advances in technology allowing improved performance and higher efficiency. However, if certain "good practice" aspects of design and implementation are not considered by the manufacturer, these technologies can also be a source of Radio Frequency Interference (RFI) which is detrimental to radio communication. This is especially problematic when attempting to receive HF transmissions which have very low power levels after traveling long distances and are easily obscured by local noise.

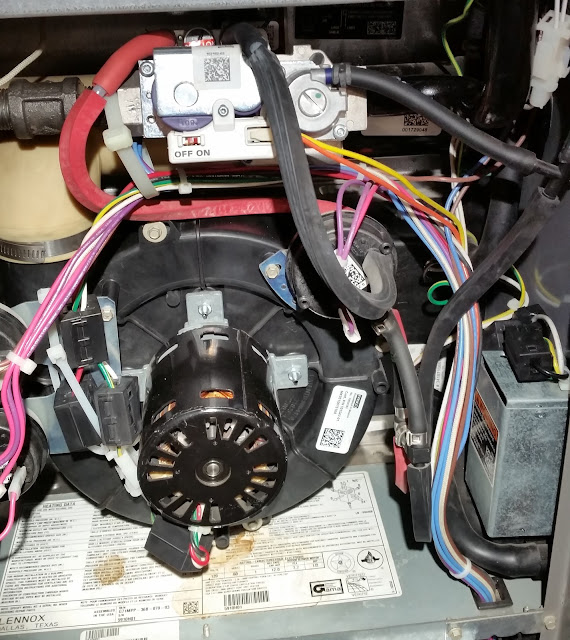

The main emitter of RFI in this particular Lennox High Efficiency forced-air direct vent gas furnace seems to be the draft inducer fan. This is a variable speed fan which acts to push the exhaust gases up the chimney since with high efficiency furnaces the exhaust temperature is too cool to depend on passive rising. The voltage reaching the motor (and hence its speed) is modulated through rapid on/off switching (PWM), a technique which inherently generates and radiates RFI without proper mitigation. The blower motor is also variable speed but does not seem to emit significant RFI like the draft inducer.

The goal of the fix should be to add impedance (resistance to Alternating Current) to any wires leaving the metal furnace enclosure so that any internally generated noise is significantly attenuated before traveling into (unshielded) wires inside the walls of the house which will radiate the noise and easily reach a nearby HF antenna. These are the 120V power supply wires (Line, Neutral, and Ground) and 5 wires which run to the thermostat.

|

| Added clip on ferrite chokes (Fair-rite VO) to 120V supply wires (L,N,G). There are at least 2 chokes in series per wire (not all visible). |

|

| This is the inducer fan motor itself. Disconected pigtail to twist wires and added 3 clip on chokes in series. |

|

| Another view: chokes added to inducer fan wiring. Where there was room I added a choke per individual wire. Sometimes the chokes went over multiple wires; both ways add impedance. |

Before this filtering every time the furnace came on 40m and above were wiped out by noise. Now it makes no noticeable difference whether the furnace is running or not.

No comments:

Post a Comment